Horizontal Directional Drilling in Malaysia: A Game-Changer in Trenchless Technology

Horizontal directional drilling (HDD) has revolutionized the construction and infrastructure sector in Malaysia, offering an efficient, environmentally friendly, and cost-effective method for underground pipeline and cable installation. As urbanization and infrastructure development continue to expand, HDD has become an essential technology for minimizing disruption while ensuring the seamless installation of utilities.

This article explores the significance of horizontal directional drilling in Malaysia, its applications, advantages, and the key factors driving its growth in the country.

Understanding Horizontal Directional Drilling

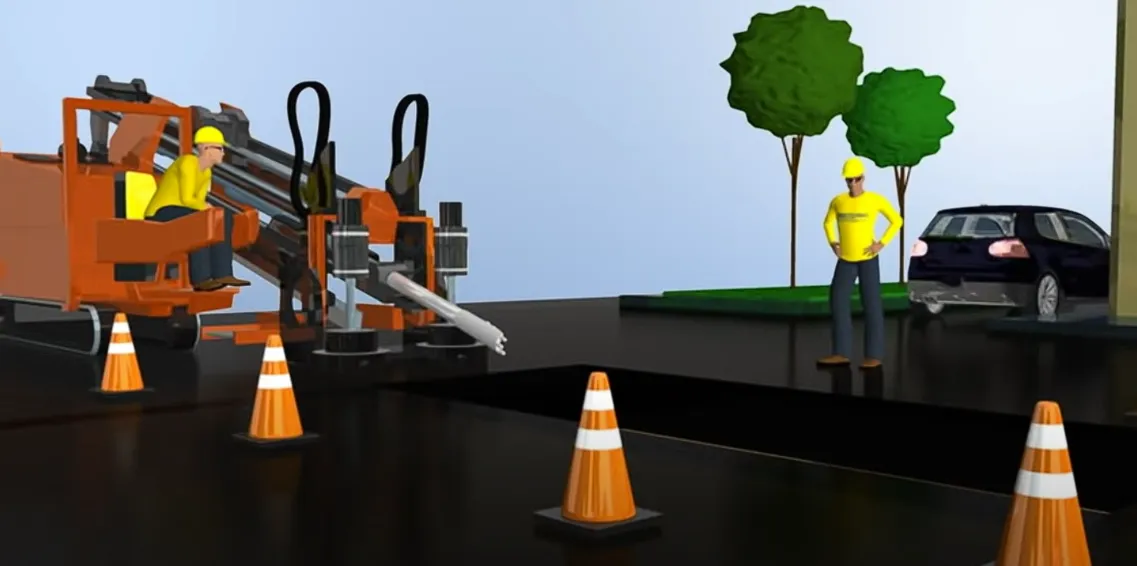

Horizontal directional drilling is a trenchless technology that allows for the precise installation of underground pipelines, conduits, and cables with minimal surface disturbance. The process involves three primary stages:

- Pilot Hole Drilling – A drill rig creates a small-diameter pilot hole along a predetermined path using a guided drill bit.

- Reaming – Once the pilot hole is completed, a reamer is used to enlarge the hole to the required diameter.

- Pipeline Installation – The final step involves pulling the pipeline or conduit through the pre-drilled hole, completing the underground installation.

Unlike traditional open-cut trenching, HDD minimizes environmental impact, reduces excavation needs, and is ideal for urban areas where surface disruption must be kept to a minimum.

The Growth of Horizontal Directional Drilling in Malaysia

Malaysia’s increasing demand for robust infrastructure and sustainable development has accelerated the adoption of horizontal directional drilling. Several factors have contributed to its growth:

1. Urbanization and Infrastructure Development

With rapid urbanization, cities such as Kuala Lumpur, Penang, and Johor Bahru require efficient underground utility installation methods that do not disrupt daily activities. HDD is widely used for water pipelines, gas distribution networks, and fiber-optic cables, supporting the nation’s infrastructure expansion.

2. Government Initiatives and Regulations

The Malaysian government has prioritized sustainable development through initiatives such as the 12th Malaysia Plan (2021-2025), which emphasizes eco-friendly construction methods. HDD aligns with these goals by reducing land disturbance and preserving natural habitats.

3. Advancements in Drilling Technology

Improved drilling equipment, real-time monitoring systems, and enhanced drill bit designs have made HDD more efficient and accurate. These advancements allow contractors to complete projects faster while ensuring precise underground installations.

4. Demand for Trenchless Solutions in Sensitive Areas

HDD is particularly beneficial in environmentally sensitive regions, such as national parks and water bodies. It is frequently used in Malaysia for projects crossing rivers, highways, and congested urban areas where traditional excavation is not feasible.

Applications of Horizontal Directional Drilling in Malaysia

1. Oil and Gas Pipeline Installation

HDD is extensively used for installing pipelines that transport oil and natural gas across Malaysia. The method ensures the safe and secure placement of pipelines under roads, rivers, and densely populated areas.

2. Telecommunication and Fiber Optic Cable Laying

The demand for high-speed internet and 5G connectivity has led to increased fiber-optic cable installations. HDD enables telecommunication companies to deploy underground cables efficiently without disrupting roads and urban landscapes.

3. Water Supply and Sewer Systems

Malaysia’s growing population necessitates expanded water distribution and sewage systems. HDD allows for the installation of water pipelines and sewer lines with minimal environmental impact, reducing project timelines and costs.

4. Electrical Conduit Installation

To meet the country’s energy demands, underground electrical conduits must be installed efficiently. HDD provides a reliable solution for laying electrical cables while minimizing surface excavation.

Advantages of Horizontal Directional Drilling

The benefits of horizontal directional drilling have made it the preferred choice for many construction projects in Malaysia. Some key advantages include:

1. Minimal Surface Disruption

HDD eliminates the need for extensive excavation, making it ideal for projects in busy urban areas. Roads, sidewalks, and landscapes remain largely undisturbed.

2. Cost-Effectiveness

Although the initial investment in HDD equipment may be high, the overall cost savings from reduced labor, shorter project durations, and minimal restoration expenses make it an economical choice.

3. Environmental Sustainability

HDD helps protect Malaysia’s natural landscapes by reducing soil erosion, preserving ecosystems, and preventing water contamination. This makes it a sustainable solution for infrastructure development.

4. Increased Efficiency and Accuracy

Advanced drilling techniques and GPS-guided systems ensure precise underground installations. HDD is particularly effective for long-distance projects requiring high accuracy.

5. Suitability for Various Soil Conditions

Malaysia’s diverse geographical landscape includes rocky terrains, soft soils, and swampy areas. HDD can adapt to various soil conditions, making it a versatile drilling method.

Challenges and Future of HDD in Malaysia

Horizontal directional drilling is playing a crucial role in Malaysia’s infrastructure development, offering a sustainable and efficient solution for underground utility installations. With rapid urbanization and growing demands for improved infrastructure, HDD provides a reliable alternative to traditional excavation methods.

As technology continues to evolve and government support increases, the future of horizontal directional drilling in Malaysia looks promising. By embracing this innovative technique, Malaysia can achieve its development goals while preserving its natural environment and minimizing disruptions to urban life.