Horizontal Directional Drilling (HDD) has become a game-changer in the construction and infrastructure sectors. It is a trenchless technology that allows the installation of underground utilities such as pipelines, telecommunications cables, and electrical conduits with minimal surface disruption. This method has gained immense popularity due to its efficiency, environmental benefits, and cost-effectiveness. In this article, we will explore the process, advantages, applications, and challenges associated with horizontal directional drilling.

What is Horizontal Directional Drilling?

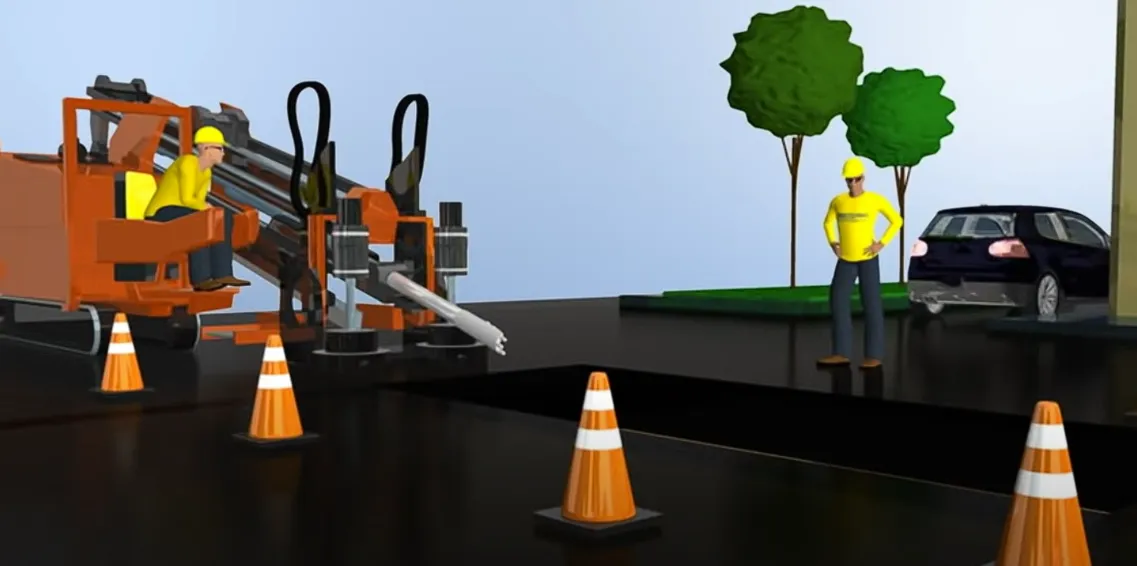

Horizontal Directional Drilling (HDD) is an advanced technique used for the installation of underground utilities without the need for extensive excavation. Unlike traditional trenching methods, HDD minimizes surface disturbance, making it ideal for urban areas, environmentally sensitive locations, and projects that require crossing obstacles like rivers, roads, and railways.

The HDD process involves three primary stages:

- Pilot Hole Drilling – A small-diameter pilot hole is drilled along the predetermined path using a drill rig. A guidance system ensures accuracy.

- Reaming – The pilot hole is gradually enlarged using reaming tools to accommodate the utility pipe.

- Pipe Installation – The prefabricated pipe is pulled through the enlarged hole and secured in place.

This method allows precise control over depth and alignment, ensuring optimal utility placement.

Advantages of Horizontal Directional Drilling

The growing adoption of HDD is due to its numerous benefits over conventional excavation methods:

Minimal Surface Disruption

HDD does not require extensive digging, making it ideal for projects in busy urban areas where road closures and large-scale excavations are impractical.Environmental Benefits

Since HDD reduces soil displacement and does not disrupt natural habitats, it is an eco-friendly alternative to open-cut trenching. This is particularly important in projects near wetlands, rivers, and other sensitive environments.Cost-Effectiveness

While the initial investment in HDD technology may be higher, the reduced labor, restoration, and traffic management costs make it a more economical option in the long run.Faster Installation

HDD projects are completed faster compared to traditional trenching, reducing downtime for businesses, communities, and infrastructure projects.Versatility

HDD can be used for various types of ground conditions, including soft soils, rock formations, and beneath water bodies. This adaptability makes it suitable for a wide range of applications.

Applications of Horizontal Directional Drilling

HDD is widely used across different industries, offering efficient solutions for underground utility installations. Some key applications include:

Oil and Gas Pipelines

HDD is extensively used for laying pipelines beneath rivers, highways, and populated areas, ensuring uninterrupted transport of oil and natural gas.Telecommunications and Fiber Optics

The demand for high-speed internet and advanced telecommunications infrastructure has led to an increased need for HDD in laying fiber optic and broadband cables.Water and Sewer Systems

HDD allows for the installation of water mains and sewer lines without disrupting existing roadways and structures. This is particularly beneficial for upgrading aging infrastructure in urban areas.Electric Power Cables

Underground electrical distribution networks require HDD for seamless installation without interfering with above-ground structures.Municipal and Public Infrastructure Projects

HDD plays a crucial role in city planning, allowing municipalities to install utilities while preserving green spaces and minimizing traffic disruptions.

Challenges of Horizontal Directional Drilling

Despite its many advantages, HDD does come with certain challenges:

High Initial Costs

The specialized equipment and technology required for HDD projects can lead to higher upfront costs compared to traditional trenching methods. However, the long-term savings often outweigh the initial investment.Complexity of Ground Conditions

Certain geological conditions, such as hard rock or unstable soils, can make drilling difficult and require advanced techniques to ensure successful completion.Risk of Inadvertent Returns (Frac-Outs)

During drilling, there is a possibility of drilling fluid escaping into the surrounding environment. Proper planning and monitoring are necessary to mitigate this risk.Skilled Workforce Requirement

HDD requires trained operators and engineers to ensure precise execution. A shortage of skilled workers can pose a challenge for some companies.Regulatory Compliance

HDD projects must adhere to environmental and safety regulations, which may vary by region. Obtaining permits and ensuring compliance can be time-consuming.

Future of Horizontal Directional Drilling

The future of HDD looks promising, driven by increasing infrastructure development and the growing demand for sustainable construction practices. Technological advancements such as automated drilling systems, real-time monitoring, and improved drilling fluids are expected to enhance efficiency and reduce environmental impact.

Additionally, the push for underground utility installations in urban areas to improve aesthetics and safety will continue to boost the adoption of HDD. Governments and private entities are recognizing the long-term benefits of trenchless technologies, leading to increased investments in HDD projects.

Conclusion

Horizontal Directional Drilling is a revolutionary method that has transformed the way underground utilities are installed. Its ability to minimize disruption, reduce environmental impact, and improve project efficiency makes it a preferred choice for modern infrastructure development. While there are challenges associated with HDD, advancements in technology and skilled labor training are addressing these issues, making it an even more viable option for the future.

As industries continue to prioritize sustainability and efficiency, HDD will remain at the forefront of underground construction techniques, ensuring that essential utilities are installed with minimal impact on the environment and communities.